Aging Parents, Dangerous Stairs, and Taiwan’s Humid Reality

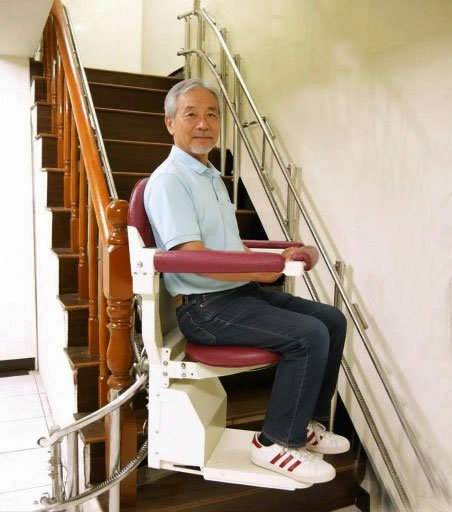

Families need to ensure a safer staircase for elderly parents

Stainless steel stairlifts are becoming essential for families in Taiwan, worried about aging parents navigating steep or narrow stairways. For many adult children, the main anxiety is, ‘Are my parents safe on the stairs when I’m not there?’.

Busy families can’t always be there to help, and they all share the same fears:

- A slip caused by fatigue or poor coordination

- A misstep while carrying something heavy

- A fall caused by poor vision

Humidity: Taiwan’s hidden safety risk

Taiwan is a tropical island that experiences heat, rain and humidity, exacerbating corrosion and rust on the metal based products and devices, resulting in safety and durability issues. Installing a stairlift with the wrong materials can compromise performance for the long-term.

The table below lists the commonly used metal used in StairLift construction.

Metals commonly used in Stairlifts.

| Material | Type | Typical Alloy Composition |

|---|---|---|

| SUS304 Stainless Steel | Austenitic Stainless Steel | ~70% Iron (Fe) 18–20% Chromium (Cr) 8–10.5% Nickel (Ni) ≤2% Manganese, Silicon, Carbon |

| SS41 Mild Steel (sometimes referred to as iron) | Low‑Carbon Steel | ~98–99% Iron (Fe)0.05–0.25% Carbon (C)Small amounts of Mn, Si, P, S |

| A6061 Aluminum | Aluminum Alloy | 95–97% Aluminum (Al) 0.8–1.2% Magnesium (Mg) 0.4–0.8% Silicon (Si) Trace Cu, Cr, Fe |

Why Stainless Steel Stairlifts Are Built for Taiwan’s Climate

After evaluating metal materials, staircase structures, humidity levels, and daily usage needs, Cityfly engineers designed products built with:

- SUS304 stainless steel rails

- Solid (not hollow) curved rail construction

- SUS420J2 steel wheels

This configuration directly addresses the four concerns every family has when choosing stainless steel stairlifts for safety, durability, comfort, and space.

Highest Safety Factor: Stainless Steel Rails That Don’t Deform or Crack

The rail is the backbone of any stairlift. Its tensile strength determines how well it handles long-term weight and impact.

For most families, stainless steel stairlifts are the best choice that maintains long-term structural integrity while being subject to daily weight stress and abrasion.

| Track Material | Tensile Strength (kg/mm²) | Safety Rating |

|---|---|---|

| Stainless Steel SUS304 | 53+ | ★★★★☆ (Highest) |

| Mild Steel SS41 | 41+ | ★★★☆☆ |

| Aluminum A6061S | 18+ | ★☆☆☆☆ |

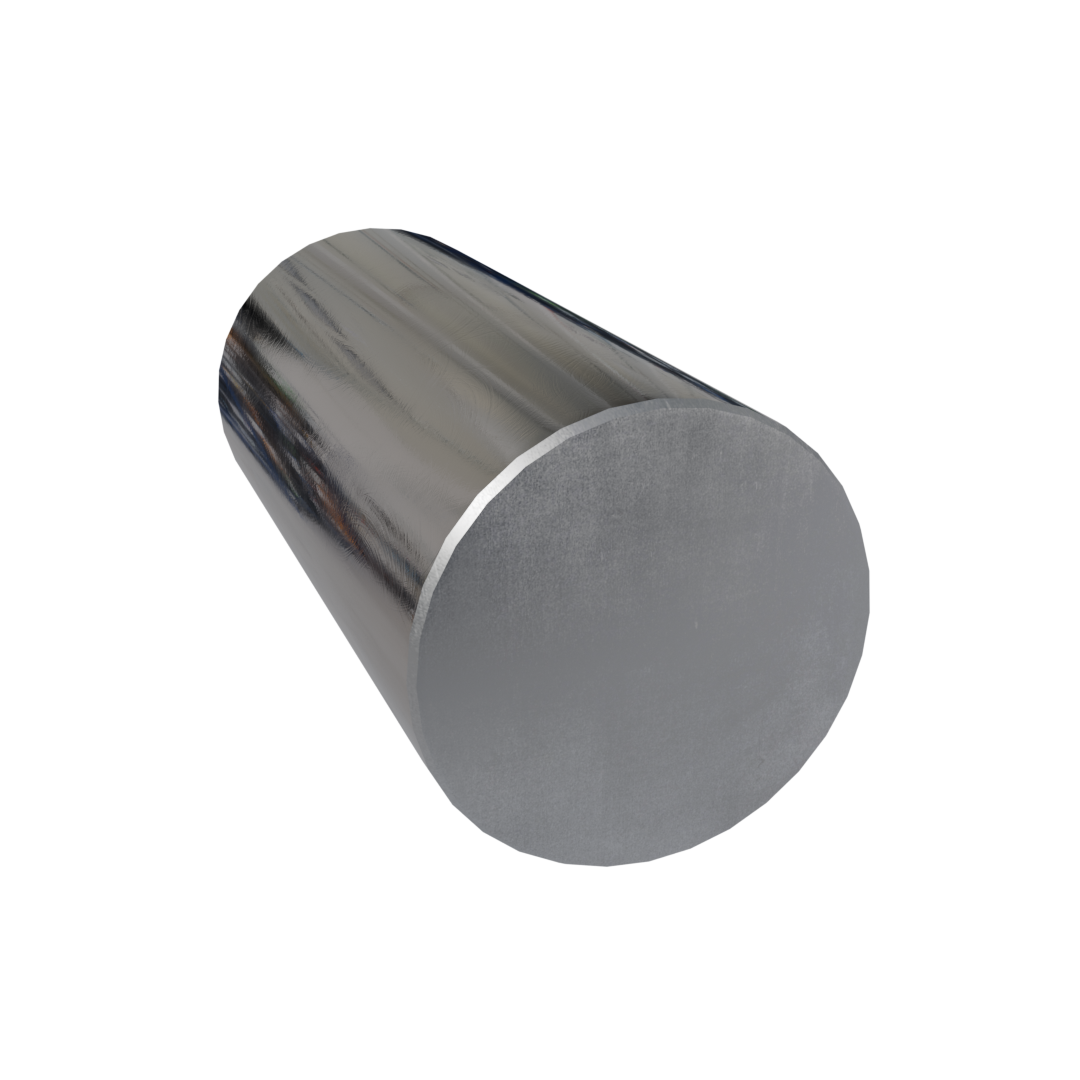

304 Stainless Steel (solid) rails

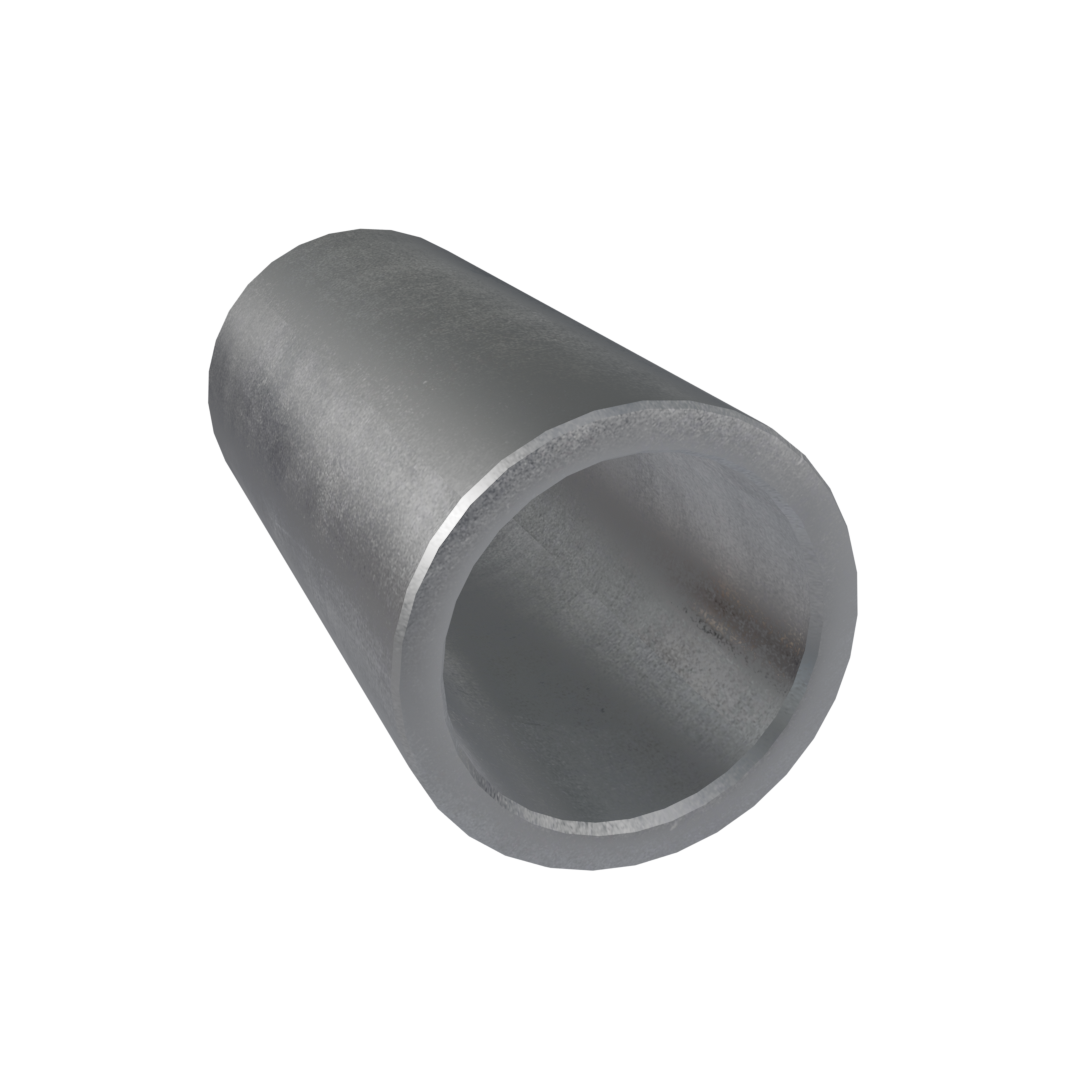

A6061 Aluminum (hollow tube rails)

SS41 Mild Steel (hollow tube rails)

Maximum Stair Space: Stainless Steel Bends Tight Without Cracking

In Taiwan’s narrow staircases, every centimeter matters. To keep the rail close to the handrail, the material must bend tightly without cracking, which is rated on the so-called elongation factor. Stainless steel stairlifts with high elongation numbers are ideal for stairways with restrictive spaces.

SUS304’s tight bending radius ideal for stairways with restricted spaces. The dotted line represents the wider path of most Aluminum or Mild Steel rails with low elongation

SUS304’s high elongation allows the rail to hug the staircase closely, keeping the width of the stairway spacious for foot traffic.

What Is Elongation and Why Does It Matter?

Elongation is a metal’s ability to stretch without cracking when bent during formation. High elongation allows stainless steel stairlifts to form tight curves while staying strong — essential for L-turns, U-turns, and narrow stairways.

| Material | Elongation | Bending Capability |

|---|---|---|

| Stainless Steel SUS304 | 35%+ | ★★★★☆ (Best) |

| Mild Steel SS41 | 20%+ | ★★☆☆☆ |

| Aluminum A6061S | 16%+ | ★☆☆☆☆ |

Smooth, Comfortable Ride: Solid Rails Reduce Vibration

Any shaking or vibration during a ride can be alarming for elderly, generally sensitive to danger.

A stairlift used daily must feel stable and smooth. Solid stainless steel rails resist deformation and vibration, giving stainless steel stairlifts a smoother ride than hollow-tube systems.

- Solid stainless steel rails → minimal vibration

- Hollow tube rails found with Aluminum and Mild Steel → prone to bending and shaking

High Corrosion Resistance Factor

Corrosion resistance becomes one of the most important factors when choosing a stairlift rail material. SUS304 stainless steel (or 304 Stainless Steel) performs the best because its chromium content forms a stable oxide layer that prevents rust from forming on the surface.

SS41 mild steel (sometimes called Iron), which is mostly iron with very little carbon, has no protective alloying elements—so it rusts quickly when exposed to moisture, especially in older homes with poor ventilation.

A6061 aluminum does not rust like iron‑based metals, but it can suffer from pitting corrosion, where small holes form on the surface over time due to humidity and salt in the air.

These differences make stainless steel the most reliable long‑term choice for stairlifts in Taiwan.

Rail pitting and rust corrosion

| Material | Corrosion Resistance | Behavior in Humidity | Notes |

|---|---|---|---|

| SUS304 Stainless Steel | ★★★★★ (Excellent) | Forms protective chromium oxide layer; resists rust | Best choice for Taiwan’s climate |

| SS41 Mild Steel (commonly mistaken as “iron”) |

★☆☆☆☆ (Poor) | Rusts quickly; requires coating or paint | Low cost but high maintenance |

| A6061 Aluminum | ★★★☆☆ (Moderate) | No rust, but prone to pitting corrosion. | Lightweight but less durable long‑term |

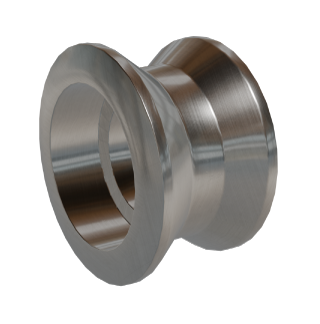

50+ Year Durability: Steel Wheels That Outlast Plastic 10:1

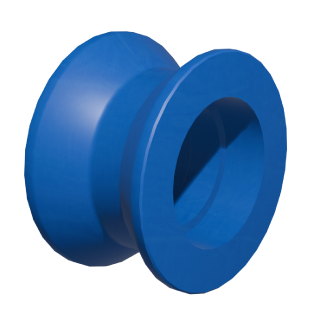

The wheels are the most heavily stressed components in stairlifts, subject to daily weight pressures and abrasion. Cityfly stairlifts use SUS420J2 steel wheels, which resist wear far better than plastic wheels also being used in stairlifts.

SUS420J2 is even harder than SUS304 used for our rails.

| Material | Tensile Strength | Abrasion Resistance |

|---|---|---|

| Stainless Steel SUS420J2 | 720 MPa | ★★★★★ |

| Plastic | 55–80 MPa | ★☆☆☆☆ |

Stainless steel stairlifts deliver decades of reliable performance, especially in humid environments.

Citifly Stainless Steel wheel.

Plastic wheels used in stairlifts.

Conclusion: A Safer Home, Happier Parents, and Peace of Mind

For families caring for aging parents, Cityfly Stainless Steel Stairlifts offer unmatched comfort, safety, durability, and long-term reliability in Taiwan’s humid climate. They provide:

- long-term structural safety

- rust-proof durability

- smooth, stable operation

- maximum stair space

- decades of reliable performance

If you’re considering a stairlift for your parents and you want a worry-free solution, stainless steel stairlifts are the safest and most future-proof choice.

Frequently Asked Questions (FAQ)

1. Why choose stainless steel stairlifts in Taiwan?

Taiwan’s humidity causes many metals to rust or deform. Stainless steel stairlifts resist corrosion and maintain structural integrity for decades.

2. Do aluminum or mild steel stairlifts rust more easily?

Yes. Aluminum and mild steel are more prone to corrosion and pitting, especially in humid homes. Stainless steel stairlifts avoid these issues.

3. What is elongation, and why does it matter?

Elongation measures how much a metal can bend without cracking during formation and still maintain structural integrity. Stainless steel stairlifts have the highest elongation, making them ideal for tight curves.

4. Do stainless steel stairlifts take up more space?

No. Because stainless steel bends tightly, the rail stays close to the handrail, preserving maximum stair width.

5. How long do stainless steel stairlifts last?

With SUS304 rails and SUS420J2 wheels, stainless steel stairlifts can operate reliably for decades.

6. Are stainless steel stairlifts safer for elderly parents?

Yes. They resist deformation, maintain stability, and provide a smoother, more secure ride — ideal for elderly users.